When a $2 million piece of military equipment arrives damaged at a forward operating base, you aren’t just facing a logistics problem – it’s a potential threat to mission success and personnel safety. Each year, inadequate packaging leads to millions of dollars in compromised military supplies and critical equipment failures.

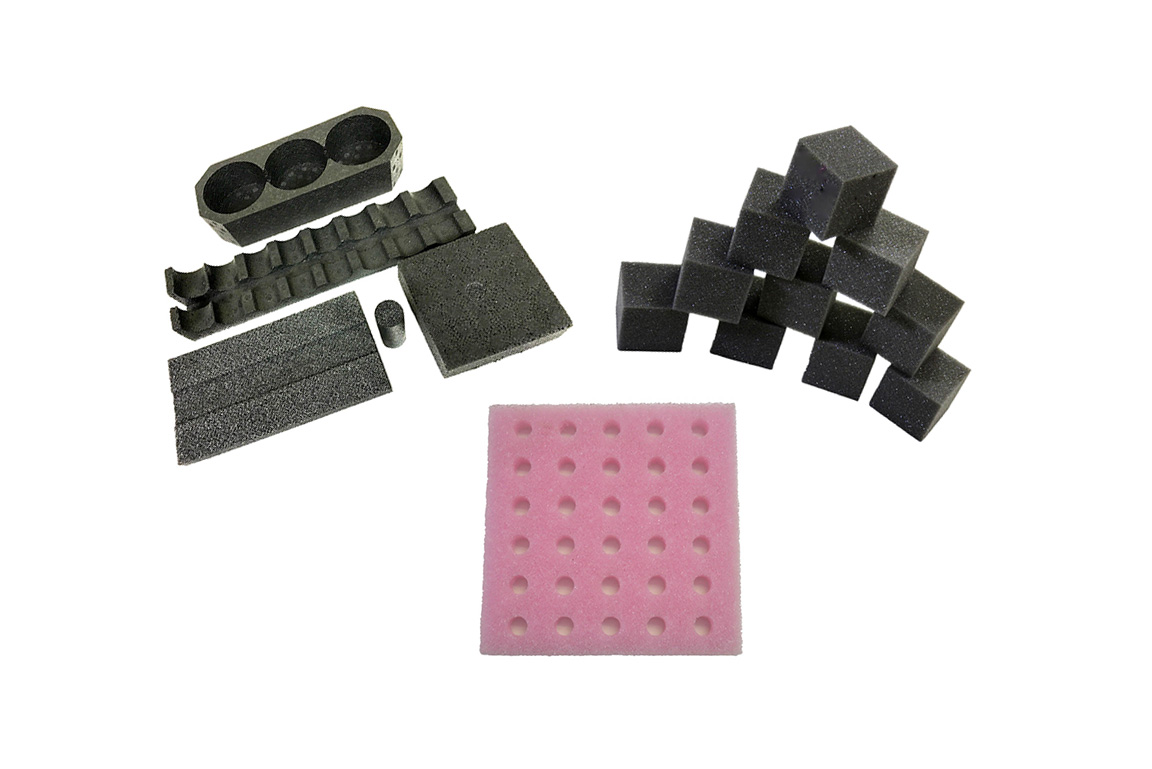

So, what is the solution to this growing problem? While much has been done to enhance the supply chain and shipment process, one of the best ways to ensure mission-critical items arrive safely is to look at engineered foam protection systems designed for military specifications.

Here at Alta Max, we’ve been providing military-grade packaging solutions since 2001 – and along the way, we’ve learned that the principles of superior foam packaging remain constant across all types of shipments.

Let’s look at the basics of military-grade foam packaging – why the right foam matters, how many shipping providers might be risking life-saving equipment, and why investing in the best packaging is key.

Military-Grade Foam Classifications

If you’re on this guide, you likely know more than the average person about how foam packaging helps items get from point A to B. But do you know the specifics about particular types of foam packaging?

Each type of foam must meet strict military specifications and performance standards for unique applications:

Polyethylene (PE) Foam

Meeting specifications like A-A-59136 and MIL-P-26514, this type of military foam packaging is the backbone of these mission-critical shipping solutions. PE foam is a versatile material that offers the best in shock absorption and vibration dampening – which is key to protecting sensitive equipment during transportation.

Polyethylene foam’s closed-cell structure offers moisture resistance as well, which makes it the best option for:

- Sensitive electronic equipment

- Optical systems and weapon components

- Communication equipment

Anti-Static Foam

Many types of military equipment are susceptible to static discharge – which can occur without warning during almost any shipping process. To help prevent static interference or damage, specialized anti-static foam meeting MIL-PRF-20092 specifications is key.

Treated to prevent electrostatic buildup, this type of foam is often used when shipping electronic components such as:

- Circuit boards

- Missile guidance systems

- Aircraft avionics

- Tactical communication devices

Polyurethane (PU) Foam

Conforming to PPP-C-1752 standards, PU foam is another excellent example of military packaging built for specific purposes.

When items being shipped require custom moldings for a precise fit, polyurethane foam is often the choice – as it can be precisely shaped to protect a variety of different shipments, such as custom weapon systems, irregularly shaped parts, and precision or calibration instruments.

Polystyrene Foam

A fourth type of key military-grade foam packaging is polystyrene foam – which is manufactured to comply with ASTM-D4819 requirements. This foam is both rigid and lightweight, offering excellent protection for heavy equipment bracing and impact-sensitive components. Load-bearing applications and temperature-sensitive materials can also benefit from high-quality polystyrene foam packaging.

What Protection Factors Make Military-Grade Foam Packaging Different?

There’s a reason why critical parts and components are shipped in the above foam packaging – any shipment could face a variety of different threat vectors along the way that could compromise equipment.

The key is knowing where your shipments may be headed and what risks they may face along the way. Different foam types offer differing levels of protection, but all are designed to give a baseline defense against common risks.

Impact & Compression Set Resistance

When equipment is transported through combat zones or airdropped into remote locations, it’s important that all components can handle force impacts far greater than standard shipping encounters. Military-grade foam packaging must absorb and dissipate extreme shock loads while keeping its protective properties – even after multiple impacts.

But what about when shipments arrive – and they have to sit for long periods of time before being used? Long-term compression set resistance is also a key factor in military-grade foam packaging, ensuring that shipments keep their same dimensions and protection over time.

Vibration & Environmental Resistance

It’s not just sudden impacts that pose a threat to shipments – consistent vibration and environmental factors can create just as much risk (and are often unseen.)

Extended exposure to vibration during transport can cause equipment failures in key components that aren’t readily seen until they fail in a mission-critical moment.

Similarly, any weather type or environment may be present, so foam packaging must be able to fight back moisture barriers and temperature-stable properties.

Static Discharge & Chemical Resistance

A single, unexpected static discharge can render electronic components useless – which can lead to expensive material and resource losses. Foam packaging – such as anti-static foam – must be used when transporting items at risk of discharge damage.

Chemicals can also pose a risk – especially when products move through environments where fuels, solvents, or other harsh chemicals are present. The foam packaging must be able to keep it’s structural integrity and protective properties, even when harsh substances are involved.

Making The Right Foam Packaging Choice

Choosing the right foam packaging for military-grade or similar shipments is a key part of the supply chain process – and skipping this step can lead to costly losses of time, material, money, and potentially personnel.

That’s why knowing how to find and procure the right foam packaging should be part of any holistic shipping process. Here are a few tips to make sure you pick the right foam packaging:

- Know your use case: Military-grade packaging can be used effectively across a wide variety of use cases, from medical equipment manufacturing to aerospace contracting. Even industrial machinery manufacturers are investing in military-grade packaging for their shipments – as these key industries need the same reliability and safety in their shipments.

- Understand the regulations: Foam packaging for military-grade purposes is often designed to meet specific requirements and regulations, such as A-A-59136 and MIL-P-26514. Knowing which is right for your shipment will help guide your final choice.

- Document your packaging choices and invest in the best: Documentation of your packaging – including what types are used and the results you experience – can impact your long-term purchasing decisions. Don’t be afraid to invest more in the best packaging!

At Alta Max, we’ve spent two decades providing both military and commercial clients with packaging solutions that meet the world’s most demanding requirements. We understand that failure isn't an option whether you are protecting military hardware or commercial equipment.

Contact our team today and browse our full set of foam packaging options – and contact us today to learn more about your options.